Global Civil and Mining has been a pioneer in successfully implementing surface mining technology into Australian projects, providing excellent results in comparison to traditional mining methods.

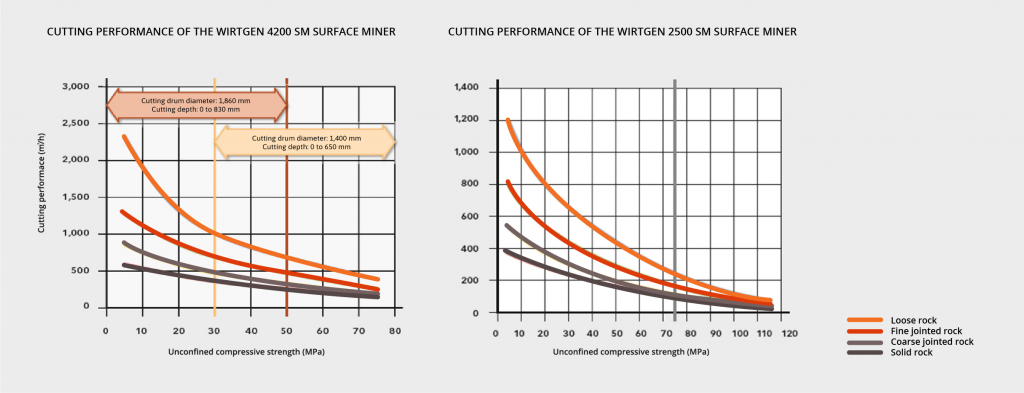

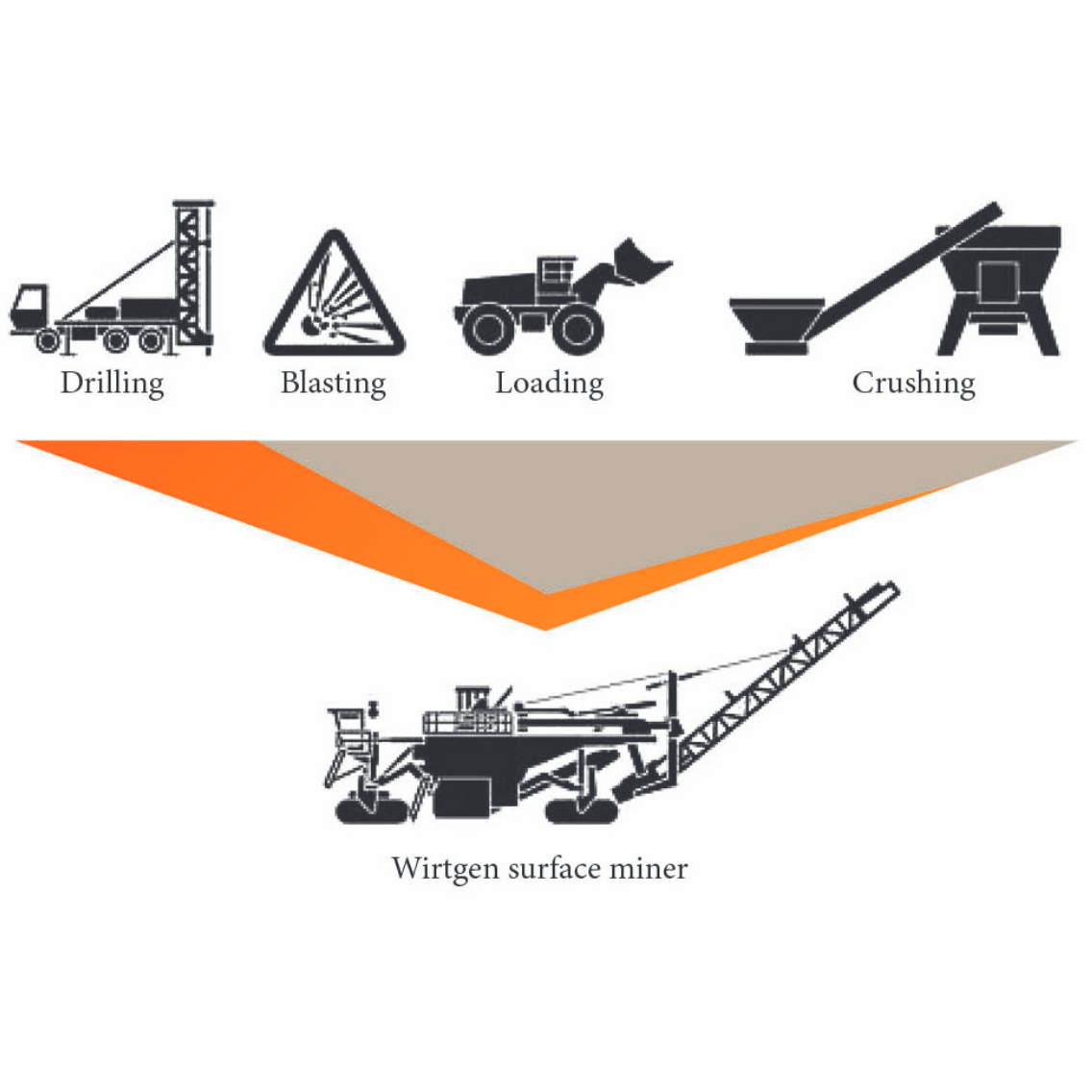

Our fleet of surface miners can cut, crush and load material in a single pass, eliminating the need for drill and blast, and primary crushing. This method reduces capital expenditure requirements and operating costs by reducing the number of machines and personnel required onsite. We provide a range of ancillary equipment, experienced staff and mine planning resources to provide a stand-alone service to resource owners and mining contractors anywhere in the world.

Global has maximised value and recovery for many clients in a range of materials such as: Iron Ore, Coal, Uranium, Limestone, Bauxite, Laterite, Salt, Nickel.